-

Bjælke

InnoVfoam fremstiller bjælkemonterede systemer, hvilket betyder, at der er monteret en plug-and-play-skumblandingsbjælke i vandsluk- ningssystemet. Et sådant kundespecifikt system er fuldt testet og leveres klar til brug. Da systemet er fremstillet skræddersyet til dimensi- onerne, spildes der ikke meget tid på montering og idriftsættelse. God forberedelse garanterer effektive projektfremskridt. Vi skræddersyr systemerne helt efter kundens ønsker og designer dem specifikt til kunderne. Ofte er levering i et hus, såsom en isoleret beholder ønskeligt og undertiden fremstilles et system i dele, der skal samles på stedet i et vanskeligt tilgængeligt rum. -

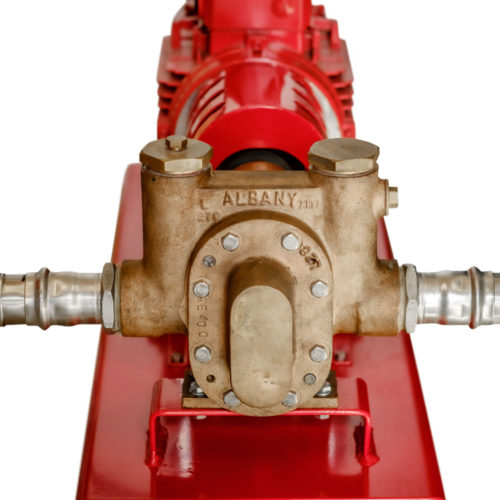

Skumkoncentratpumpe med vandturbindrev

The proportioning system with a water driven motor does not require any external energy sources, and is reliable and environmentally friendly. Pumps with water driven motors are mainly used for the InnoVdos, electronic proportioning systems and foam pump proportioners. -

Skumpumpe med dieselmotor

No additional energy source is required for driving the diesel motor. The pump with diesel motor is mainly used for the InnoVdos, electronic proportioning systems and foam pump proportioners. -

Trykskumrør

The High Backpressure Foam Generator (HBG) is a generator intended for fixed installation. Generally used for subsurface and semisubsurface foam application in storage tanks containing flammable liquids. The generators are used with most types of foam systems like foam pumps, bladder tanks or in-line proportioners. The HBG is designed to introduce air into a water/foam-concentrate mix and is always made according to customer needs. -

Inbal Vandkontrolventil

The Inbal Automatic Water Control Valve series 700DX is a pressure operated, sleeve actuated, axial valve, designed from basic concepts, with a built-in actuator, to function as a control valve in fire protection systems. The Inbal series 700DX is used as deluge, preaction, dry pipe, remote control, pressure reducing, and in other types of control valves. The standard material Inbal Valve is rated to 300 psi (21 bar) and requires a minimum line pressure of 20 psi (1.5 bar) for operation. Upon removal of the control pressure, the Inbal Valve opens instantaneously, yet very smoothly, to prevent any water hammer in the piping system. The Inbal 700DX performance and ease of resetting are not affected by vertical or horizontal installation. -

Inbal Forhandlingsventil

The Inbal Pneumatically Actuated, Double Interlocked, Preaction Valve utilizes an Inbal Dry Pipe Valve and a pneumatic pilot system. The Inbal Valve is controlled by pressure maintained in the pneumatic release system and supervisory pressure maintained in the sprinkler piping system. The Inbal Double Interlocked Preaction Valve will open to fill the sprinkler system with water only after both of the following occurrences: Activation of the release system and relieving of supervisory pressure from the sprinkler system. As soon as the releasing system and the sprinkler piping are reset, the Inbal Double Interlocked Preaction Valve resetting is merely done by activating the reset knobs. If only the pneumatic release system operates, an alarm will activate but the Inbal Valve will not open. If the sprinkler piping is damaged or a sprinkler is broken or fused but the pneumatic release system has not activated, an alarm will activate without opening the Inbal Valve. -

Tør alarmventilstation

The Inbal Dry Pipe Valve is specifically designed to control the flow of water to the dry pipe sprinkler system and to provide actuation of fire alarms when the system operates. The Inbal Dry Pipe Valve is used to separate the watersupply from the dry pipe sprinkler system, by providing a bubble tight seal as long as the valve is in a set position. The Inbal Automatic Water Control Valve which is used in this dry pipe system is a pressure operated, sleeve actuated, axial valve designed for use in fire protection systems. The trim design allows low air pressure supply to control a higher water supply pressure. -

Trykreduktionsventil

The Inbal Pressure Reducing Valve series 700D-01R01 is specifically designed for pressure regulating applications in fire protection systems. The Inbal 700D-01R01 Valve automatically reduces a higher inlet pressure to a preset delivery pressure, which remains steady and unaffected by the variations or fluctuations in the inlet line pressure. The series 700D-01R01 consists of the Inbal Valve which is a pressure operated, sleeve actuated, axial valve and a pressure reducing pilot control. The Inbal Pressure Reducing Valve maintains the downstream pressure within a narrow pressure range. If the downstream pressure changes slightly the pilot control responds immediately to modulate the Inbal Valve for the preset pressure. -

Vandstationsventilstation med trykregulering

The Inbal Pressure Control, Remote Resetting, Electrically Actuated Deluge Valve is specifically designed for use in fire protection systems which require pressure control, actuated by a remote resetting electric detection and release system. The Inbal Pressure Control, Electrically Actuated Deluge Valve, when in operation, automatically reduces a higher inlet pressure to a preset delivery pressure which remains steady and unaffected by the variations or fluctuations in the inlet line pressure. -

Sprøjtevandventilstation

The Remote Resetting, Electrically Actuated Inbal Deluge Valve is specifically designed for use in fire protection systems actuated by a remote resetting, electric detection and release system. The Inbal Automatic Water Control Valve used in this deluge system is a pressure operated, sleeve actuated, axial valve designed for use in fire protection systems. The Inbal Electrically Actuated Deluge Valve is used for automatic or manual operation. Electric activation of the Inbal deluge system requires a solenoid valve controlled by a control (fire alarm & releasing) panel either manually or by heat, smoke, or flame detectors. When the detection system operates, the control panel energizes the Solenoid Valve to open. When the Solenoid Valve is actuated either automatically or manually, or when a manual release station is operated locally or by remote, the Inbal Deluge Valve opens to flow water from all open sprinklers and/or nozzles on the system. After operation, the Inbal Valve can be reset by remote control, saving the need to approach the Deluge Valve for resetting. -

Pålidelige Skumblandere

Various types of foam proportioners for precisely proportioning foam concentrate in the water-stream of an extinguishing system can be used. The choice of proportioner depends on a number of factors: the type of extinguishing system, the required capacity, and the available energy, space (inside/outside/size) and pressure. -

Pålidelige skumblandere

Various types of foam proportioners for precisely proportioning foam concentrate in the water-stream of an extinguishing system can be used. The choice of proportioner depends on a number of factors: the type of extinguishing system, the required capacity, and the available energy, space (inside/outside/size) and pressure. -

Pålidelige Skumblandere

Various types of foam proportioners for precisely proportioning foam concentrate in the water-stream of an extinguishing system can be used. The choice of proportioner depends on a number of factors: the type of extinguishing system, the required capacity, and the available energy, space (inside/outside/size) and pressure. -

Pålidelige skumblandere

Various types of foam proportioners for precisely proportioning foam concentrate in the water-stream of an extinguishing system can be used. The choice of proportioner depends on a number of factors: the type of extinguishing system, the required capacity, and the available energy, space (inside/outside/size) and pressure. -

Flexi Dyse

The Flexi Nozzle is a high capacity deluge nozzle. Both water capacity, spread angle and jet direction can be adjusted. The larger models of the nozzles operates as a fixed monitor with water capacity up to 6000 LPM and reaching a length of 60m when in jet position and with water/foam solution. Water jet can be adjusted 30⁰ each side of centerline. -

Brandmonitor Trailer Type 3

The InnoVfoam trailer mounted fire monitors are available in various executions in order to serve a wide range of mobile firefighting applications. The InnoVfoam monitor trailers show a solid construction which is stable in all circumstances. Due to integrated foam proportioning devices, the Innovfoam monitor trailers can do their job both with water and the admixture of any foam concentrate. Depending on the monitor capacity, an InnoVfoam monitor trailer can be provided with an integrated foam concentrate tank. -

Brandmonitor Trailer Type 2

The InnoVfoam trailer mounted fire monitors are available in various executions in order to serve a wide range of mobile firefighting applications. The InnoVfoam monitor trailers show a solid construction which is stable in all circumstances. Due to integrated foam proportioning devices, the Innovfoam monitor trailers can do their job both with water and the admixture of any foam concentrate. Depending on the monitor capacity, an InnoVfoam monitor trailer can be provided with an integrated foam concentrate tank. -

Brandmonitor trailer

The InnoVfoam trailer mounted fire monitors are available in various executions in order to serve a wide range of mobile firefighting applications. The InnoVfoam monitor trailers show a solid construction which is stable in all circumstances. Due to integrated foam proportioning devices, the Innovfoam monitor trailers can do their job both with water and the admixture of any foam concentrate. Depending on the monitor capacity, an InnoVfoam monitor trailer can be provided with an integrated foam concentrate tank. -

Vandret blæsetank

The InnoVfoam bladdertank system is a system for mixing foam concentrate with water. A major advantage of the bladdertank system is that it can be installed in the main flow and subsequently it doesn't need an external energy supply. The integrated water reference test option offers a func- tionality test without foam consumption. -

Hydrantskab uden skumtank og fordeler

The InnoVfoam hydrant cabinet (type without foam concentrate tank and proportioner) is designed as a compact and reliable device. Therefore it is highly suitable for all types of helidecks. With its foot plate it can be fastened to the floor as well as a wall. When using the hydrant the fire hose can easily be unrolled and connected to the present storz couplings. Due to the light weight construction the branchpipe is easy to operate. -

Hydrantskab med skumtank og skumblander

The InnoVfoam hydrant cabinet type with foam concentrate tank and proportioner is a compact device which includes a hose reel with foam making equipment and a foam inductor with foam concentrate tank. The cabinet can be connected to a suitable water supply with sufficient water flow and pressure. The field of applications can be found within the aviation (heliports and hangars), the industry (chemical plants, refineries) and the civil sector (fuel stations, boiler rooms, auto parks). Due to the integrated foam induction, the cabinet is suitable for manual suppression of fuel fires with foam. The outstanding performance of the foam making equipment like the low expansion foam branch pipe enabled fire fighting from distance. -

Lineær glasfiberdetektion

Glas fibre detection is a revolutionary way of measuring exact temperature with help of a glas fibre detector. The reflected signal from the laser that is sent by the glass fibre is temperature sensitive and provides a precise temperature measurement on each point of the detector. With the supplied controller the detector can be devided into 256 zones and alarm criteria can be programmed per zone such as min/max temperature, rate of rise, deviation of an average etc. The system is perfectly suitable for buildings with explosion safe equipment such as chemical factories, refineries and tank terminals. Direct controlling from the fire fighting system is possible. The maximum length of 8 km offers a flexible and affordable detection device. -

Skumkop med skumgenerator

The InnoVfoam Tank Foam Generator (ITFG) with an integrated foam chamber and (separate) Foam Pourer (FP) is developed for extinguishing storage tank fires. In order to generate low expansion foam and spread it over the flammable liquid surface the device is provided with an integrated air foam generator. For ease of installation the flanged outlet usually is connected to a flanged nozzle which is welded into the tank-shell close to the tank top. -

Dyse med lavt skum

The Low expansion Foam Nozzle is designed for use in a deluge type foam sprinkler system and in- tended for use with all types of foam solutions from a separate foam proportioning system. The sprinkler has a compact and rigid construction and can be used both inside and outside; it can be mounted horizontally or vertically. -

Kraftig skumgenerator (Fixed/Portable)

The LFG, Low expansion Foam Generator is used for fixed installations. The design allows for rapid coverage of i.e. a bunded area and should be used together with a Class B foam concentrate. Due to the low expansion and the robust design the LFG is suitable for outdoor use also in harsh environment. The generators can be used with most types of foam systems like foam pumps, bladder tanks or In-line proportioners. The LFG produces a uniform heavy foam with a nominal expansion ratio of more than 10:1. -

Medium skumgenerator

The Medium Expansion Foam Generator is a generator intended for fixed installations. Generally used for coverage of bunded and diked areas, incinerator plants, loading facilities, jetties, spill fires, control of vapor relese from toxic or flamable liquid spill or protection of loading facillities where medium expantion foam is needed. The generators are used with most types of foam systems like foam pumps, bladder tanks or In-line proportioners. The generator normally operates between 3 to 5 bar inlet pressure. -

FiFi-1 Fjernbetjent brandvandsmonitor

The InnoVfoam FiFi-1 monitor type FWM-EL was designed as compact and reliable device. Horizontal and vertical positioning is accomplished by remotely controlled electric motors, equipped with insulated handles to facilitate safe manual override. The unit can be supplied either with a water branchpipe, foambranchpipe or Fog/Jet nozzle type FJN which can be adjusted between full jet and spray modes by a separate electric motor. -

Manuel styret brandmonitor

The InnoVfoam fire monitor type FWM was designed as compact and reliable device. Horizontal and vertical positioning is set manually with help of levers (FWM-3/4/6) or hand wheels (FWM-8), which enable safe manual operation. The Fog/Jet nozzle type FJN can be adjusted, by hand, between full jet and spray mode. The capacity of the unit can be manually adjusted such that the best performance possible at the given water pressure in regard to throw length and jet pattern is achieved. The monitor can be equipped with a foam branch pipe or a water branch pipe. -

Slukningsmonitor med pendulbetjening

The InnoVfoam fire monitor type FWM was developed as compact and reliable device. The manual operation (horizontally and vertically) is done by protected handles which enables safe monitorcon- trols. The Jet/Spray nozzle can be ajusted between full jet and spray by turning the nozzle-grib. Ca- pacityadjustment can be calibrated easily in order to get the best performance regarding throw length and Jet-pattern in relation to the available waterpressure on site. If supplied together with a Waterturbine, installed at the inletflange of the FWM monitor, the rotati- on of the monitor can be done automatically on waterpressure. This additional device enables safe operation in hazardous conditions without putting people into danger. -

InnovDos Foam Proportioning System

InnoVfoam has developed a foam proportioning system called "InnovDos" for adding foam concentrate to mains water without needing an external energy supply. InnovDos uses a water-driven foam pump. Its main components have been tested and approved by VdS. The system is suitable for foam proportioning in large (sprinkler) systems. -

Differenstrykblander

Various types of foam proportioners for precisely proportioning foam concentrate in the water-stream of an extinguishing system can be used. The choice of proportioner depends on a number of factors: the type of extinguishing system, the required capacity, and the available energy, space (inside/outside/size) and pressure. -

Pop-Up Dyse

Nozzle for deck integrated fire fighting system (DIFFS). Designed for installation in any deck where there is access from below for installation and to hook up water supply. The nozzle has an housing like a bulkhead pipe with lock nut and water supply connection to be installed permanently in the deck. A pop-up spray nozzle cartridge is installed in to this housing from topside. The cartridge can be removed for flushing, cleaning and pressure testing -

Pålidelige Skumblandere

Various types of foam proportioners for precisely proportioning foam concentrate in the water-stream of an extinguishing system can be used. The choice of proportioner depends on a number of factors: the type of extinguishing system, the required capacity, and the available energy, space (inside/outside/size) and pressure. -

Electronic proportioningsystem

The engineers of InnoVfoam have designed and programmed a control cabinet which injected foam concentrate into the main line without a proportioner in combination with two flow meters and a frequency controlled electric driven foam pump. This will ensure a correct mixing rate in any required precentage. Any capacity is possible and no pressure gets lost. For testing the system without the loss of foam concentrate, the system can circulate the foam concentrate back to the foam concentrate tank. For questions please contact InnoVfoam.