Linearer Glasfasendetektion

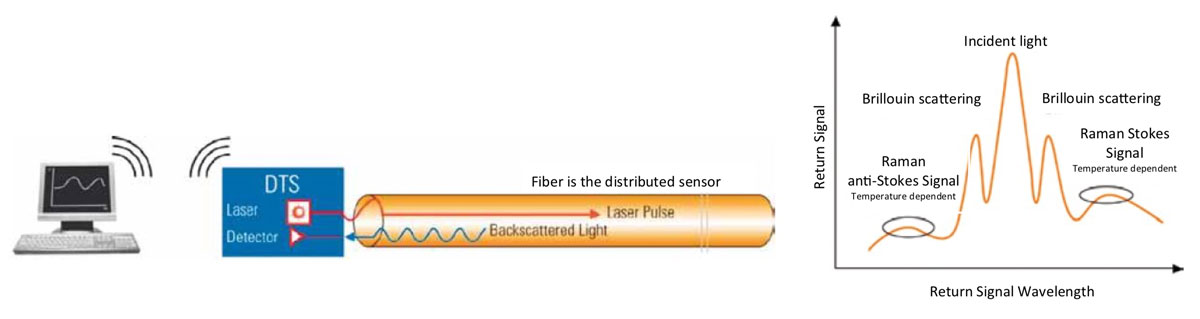

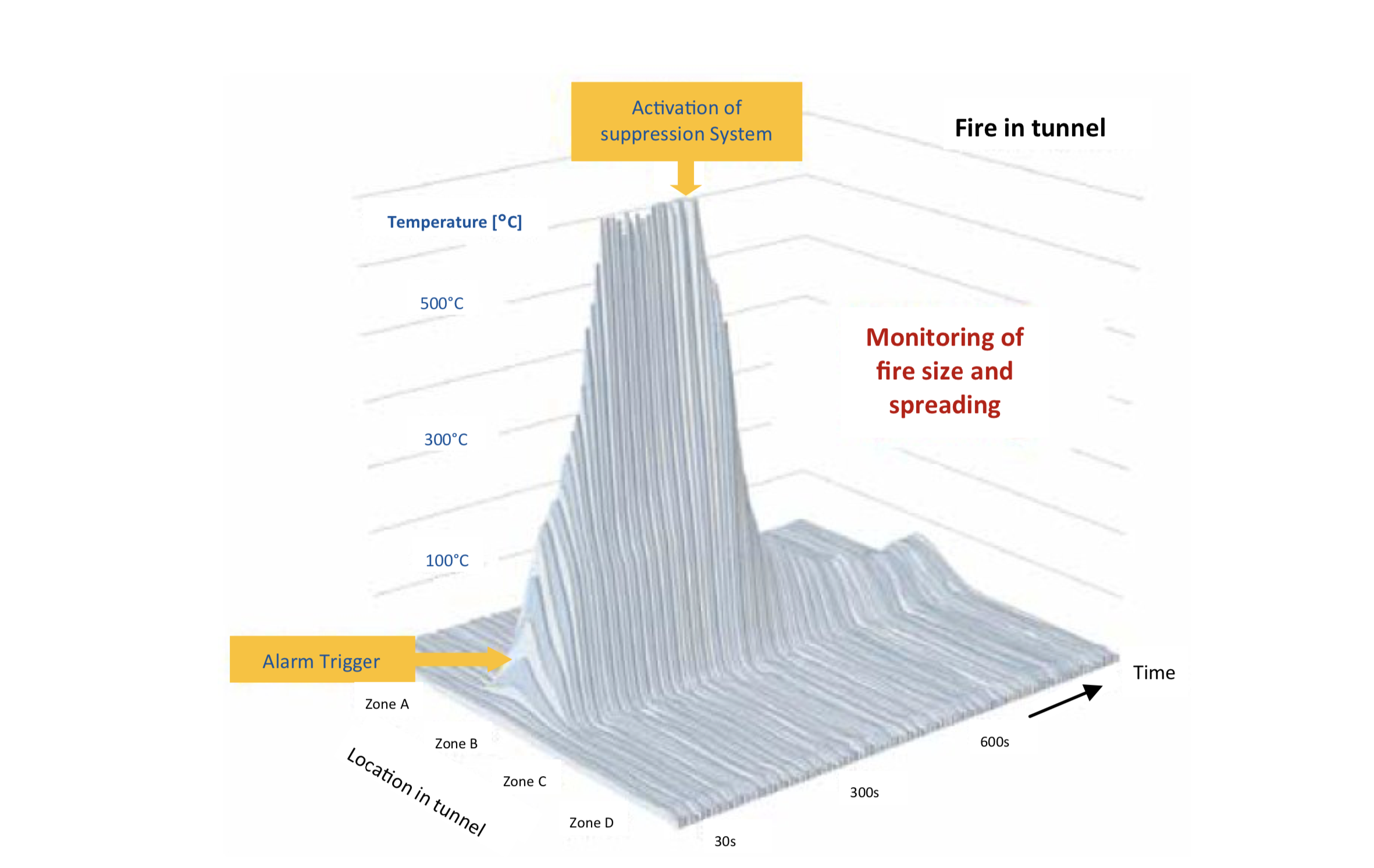

Glasfaserdetektion ist ein revolutionäres Mittel um mit Hilfe eines Glasfaserdetektors exakt die Temperatur zu messen. Das zurückgesendete Signal des von dem Glasfaser gesteuerten Lasers ist temperaturabhängig und sorgt für eine exakte Temperaturangabe an jeder Stelle des Detektors. Durch die mitgelieferte Kontrolleinheit kann der Detektor über maximal 256 Zonen verteilt werden und pro Zone kann das Alarmkriterium eingestellt werden wie: min/max Temperatur, Steigerate, Änderung in der Norm usw. Das System eignet sich hervorragend für Gebäude mit explosionsicherer Apparatur wie chemische Fabriken, Raffinerien und Tank Terminals. Eine gezielte Ansteuerung des Löschsystems ist möglich. Die maximale Länge von 8 km bietet ein flexibeles und bezahlbares Detektionsmittel.InnoVfoam’s “Linear Heat Series” has been designed to minimize your operational costs and to work with maximum reliability under severe environmental conditions like:

- Dirt, Dust, Corrosive Atmospheres

- High Humidity

- Dynamic Temperature Fluctuations

- Solvent Vapors, Radioactive Radiation

- ATEX Classified Areas

In general safety systems demand highly reliable and extremely quick fire detection. Solutions need to be immune to interference and free of false alarms. They should continue to monitor regardless of the enormous heat and rapid spread of smoke. With conventional means, fulfilling these requirements requires complicated installation, commissioning and maintenance efforts. This is particularly the case in large, distributed manufacturing facilities, refineries, power plants, silos, ware- houses, cold stores, conveyor belt systems, cable trays and tunnels.

InnoVfoam’s DTS systems address these problems by using standard fiber optic cable as a precise, distributed heat sensor. They are easy to install and virtually maintance free. The fiber optic cable can withstand extremely high temperatures and can be several thousand meters long.

Drawing

Specifications

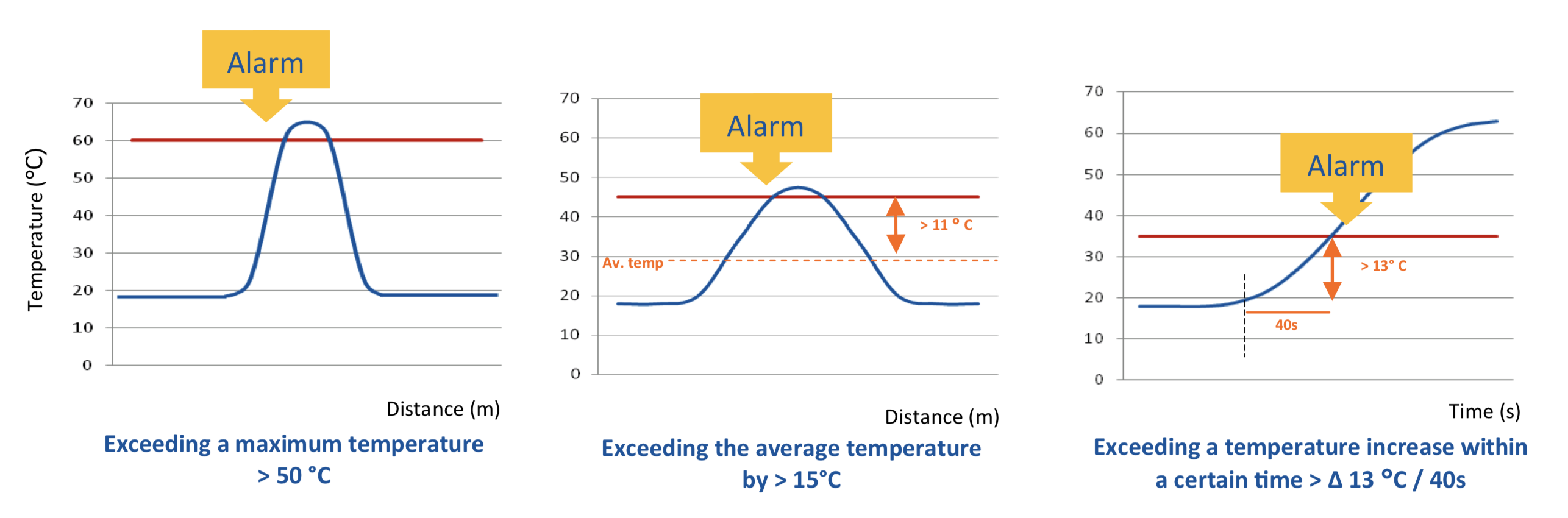

- Up to 256 freely configurable alarm zones with up to 5 alarm parameters per zone:

- static maximum

- adaptive maximum (takes ambient temperature into account)

- three individual temperature gradients to cover different heat risings

- Fiber break detection and localization

- Real loop / dual ended measurement mode with automatic fiber break recovery

- Direct triggering of alarms can be performed with up to 256 potential-free relay out- puts, can be used for direct activation of sprinklers, horns, ventilation system and much more

- DTS Calibration Wizard allows easy calibration of each fiber segment, accounting for splices, connectors, or variances in fiber properties

- Provides an easy to understand loss (db) trace like an OTDR

Certificaten

- VdS EN54-5, lass A1

- Product Safety: IEC 61010-1:2001 and deviations acc. to CAN/CSAC22.2 No. 61010-

04; UL 61010-1:2004 - Laser Safety: IEC 60825-1:2001

- FDA ackn. for Laser Sources: Class 1M; FDA 21CFR 1040.10+ Laser Notice No. 50 Electro-Magnetic Compatibility: IEC 61326:2002

- Environmental Testing: IEC 60068-2-6/-64; IEC 60068-2-27

- ISO 9001:2000

- UL 521, ULC S530

Sie sind sich nicht sicher, welche Lösung für Ihr Unternehmen geeignet ist?

Sie sind in unserem Büro immer willkommen, damit wir gemeinsam eine geeignete Lösung für Ihr Löschproblem finden können. Wünschen Sie weitere Informationen zu diesem System? Sie können unsere umfassende Broschüre unten kostenlos herunterladen.