Water turbine operated fire monitor

The InnoVfoam fire monitor type FWM was developed as compact and reliable device. The manual operation (horizontally and vertically) is done by protected handles which enables safe monitorcon- trols. The Jet/Spray nozzle can be ajusted between full jet and spray by turning the nozzle-grib. Ca- pacityadjustment can be calibrated easily in order to get the best performance regarding throw length and Jet-pattern in relation to the available waterpressure on site. If supplied together with a Waterturbine, installed at the inletflange of the FWM monitor, the rotati- on of the monitor can be done automatically on waterpressure. This additional device enables safe operation in hazardous conditions without putting people into danger.The InnoVfoam fire monitor type FWM was developed as compact and reliable device. The manual operation (horizontally and vertically) is done by protected handles which enables safe monitorcontrols. The Jet/Spray nozzle can be ajusted between full jet and spray by turning the nozzle-grib. Capacityadjustment can be calibrated easily in order to get the best performance regarding throw length and Jet-pattern in relation to the available waterpressure on site. If supplied together with a Waterturbine, installed at the inletflange of the FWM monitor, the rotation of the monitor can be done automatically on waterpressure. This additional device enables safe operation in hazardous conditions without putting people into danger.

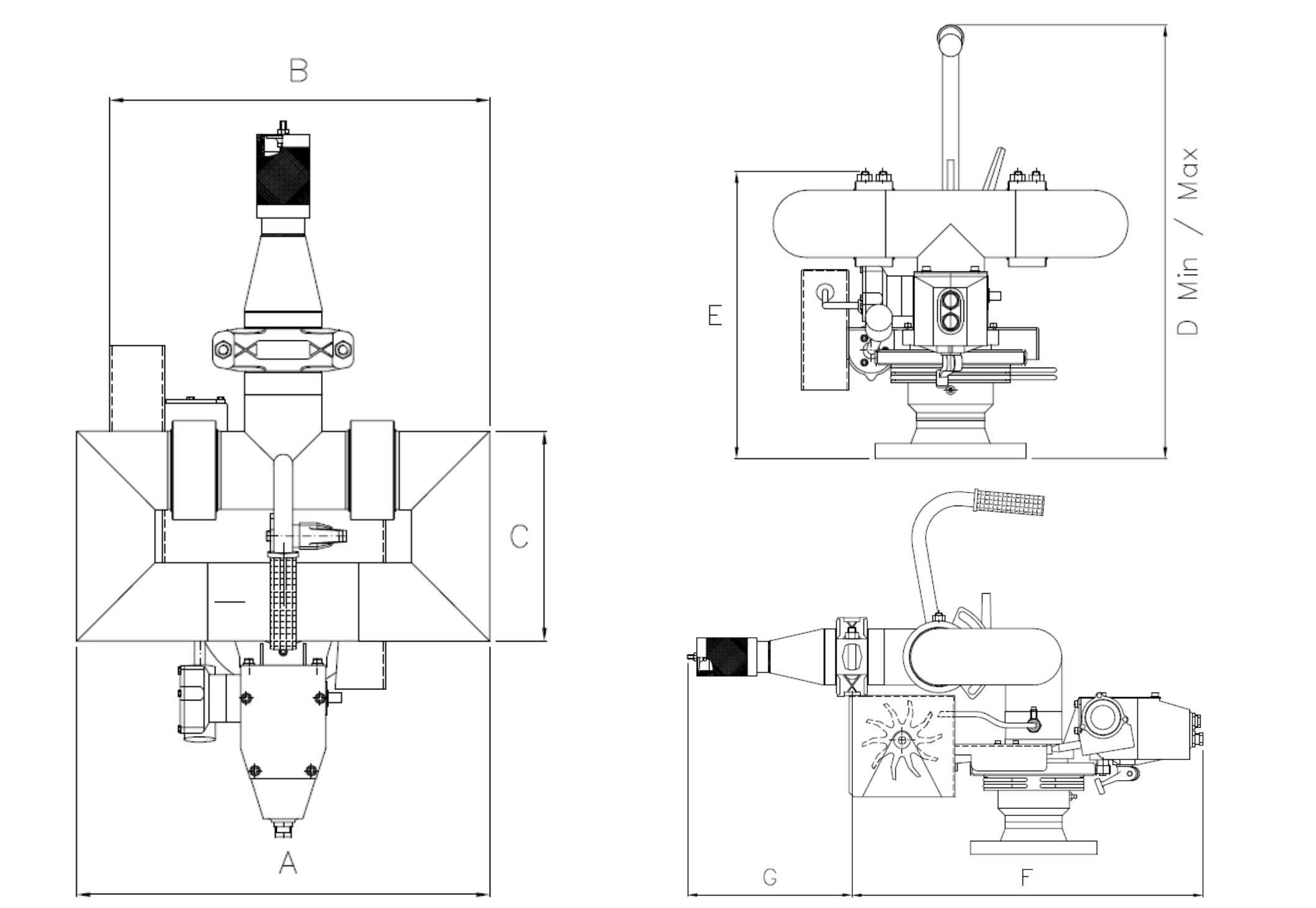

Drawing

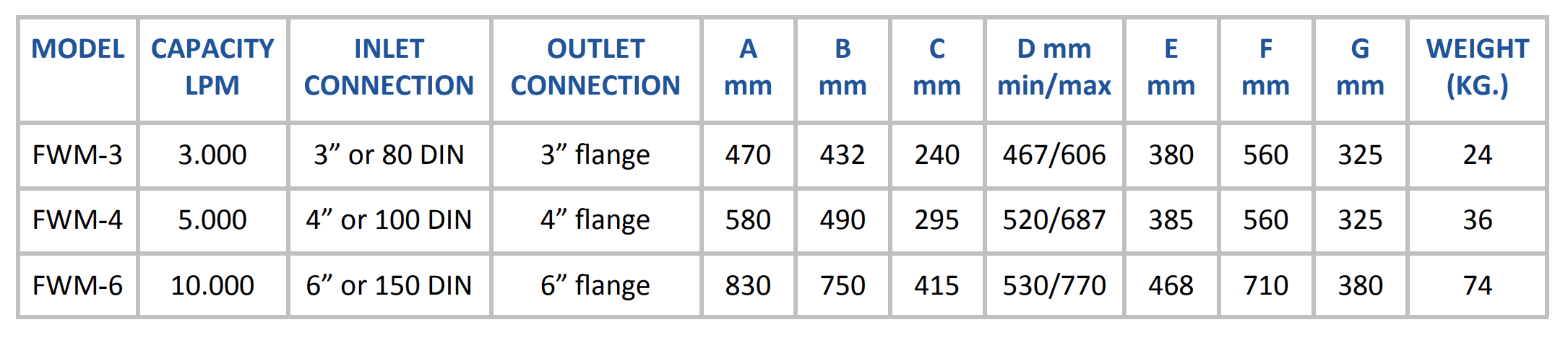

Dimensions

Characteristics FWM Monitor

Design pressure: 16 bar

Max. working pressure: 16 bar

Test pressure: 24 bar

Rotation: 360˚

Elevation: + 75˚ – 75˚

Body material: Stainless steel

Finish: Primer and red epoxy paint (RAL 3000)

Characteristics BA Nozzle

Body material: Stainless Steel

Nozzle manually adjustable: From jet to spray

Max. Spray angle: 120°