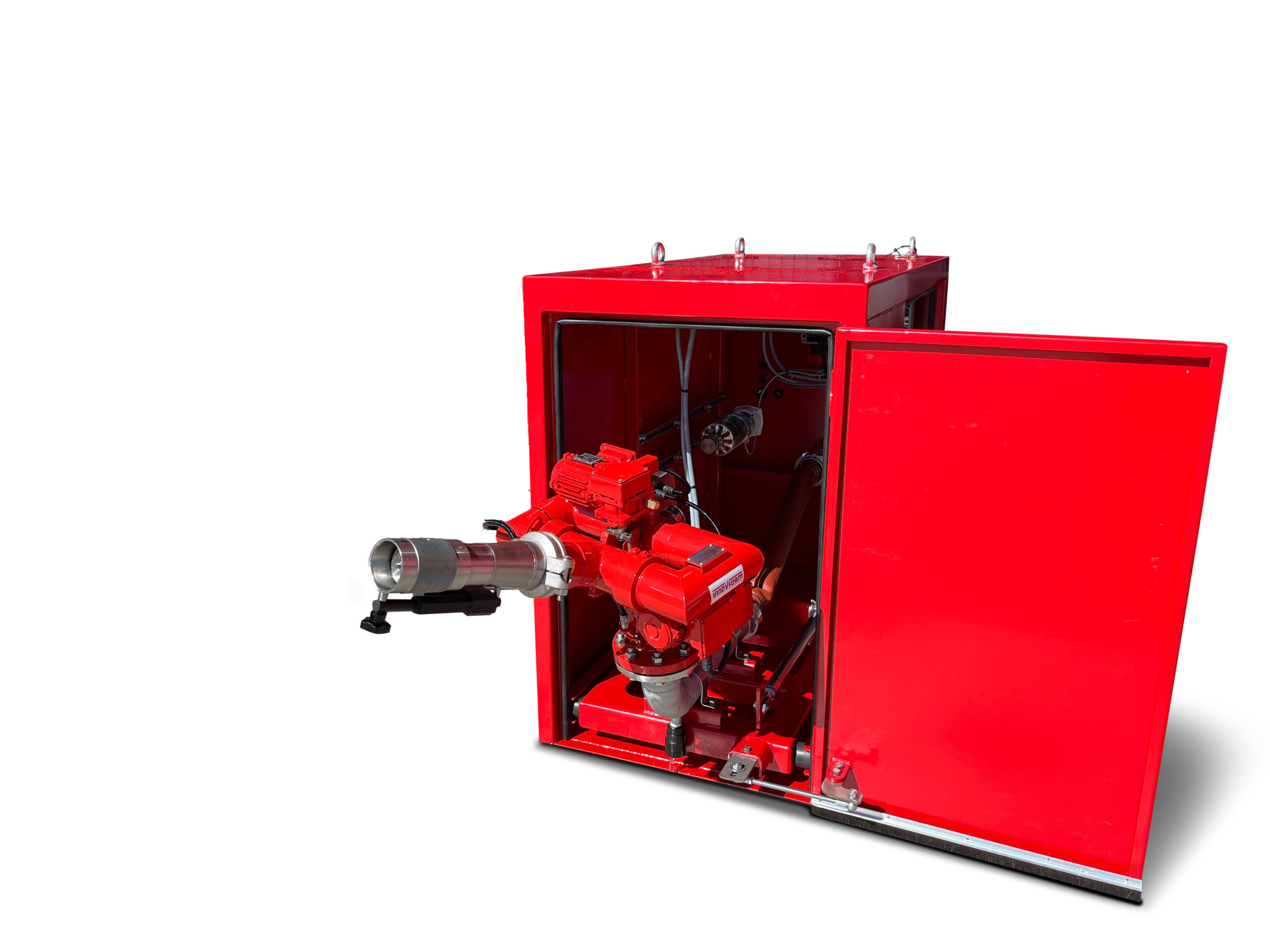

Because dust accumulation on electrical contacts, motors, and other moving parts can reduce the operation of the system and thus its reliability, the fire monitors are stored in dust‑protected housings; the Lafette cabinet, when not in use.

These housings automatically open a door upon activation, after which the fire monitors roll out automatically. After use, the fire monitors automatically return to their idle position, roll back into the housing, and the doors close by themselves.

All side panels of the housings are removable to facilitate maintenance and repair work.

ADVANTAGES

- Rapid and effective firefighting

Thanks to the powerful water and foam jets, fires can be tackled at an early stage. - Complete area coverage

The monitor can rotate both horizontally and vertically, reaching every point in a bunker. - Safe remote operation

Can be operated from a crane cabin or via a portable control unit, either wired or wireless. - Automation options

Can be connected to a PLC system and a thermal imaging camera for automatic activation. - Protection and easy maintenance

The dust‑protected housing shields the monitors from dirt and dust, and all side panels are removable for easy maintenance.

APPLICATIONS

- Waste incineration plants

- Storage of hazardous materials

- Industrial halls

- Port and transshipment terminals

- Recycling centers

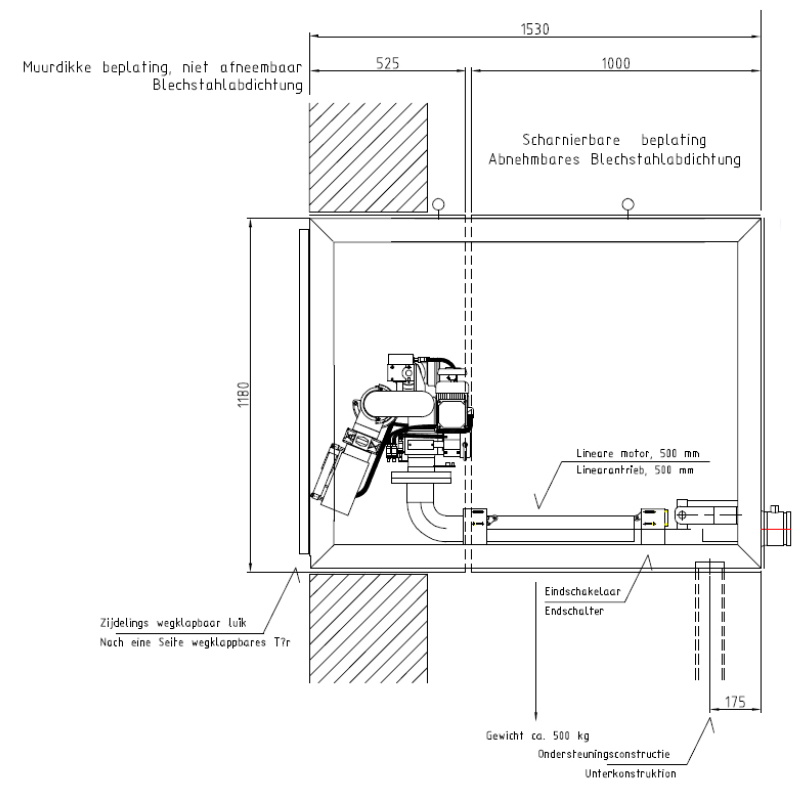

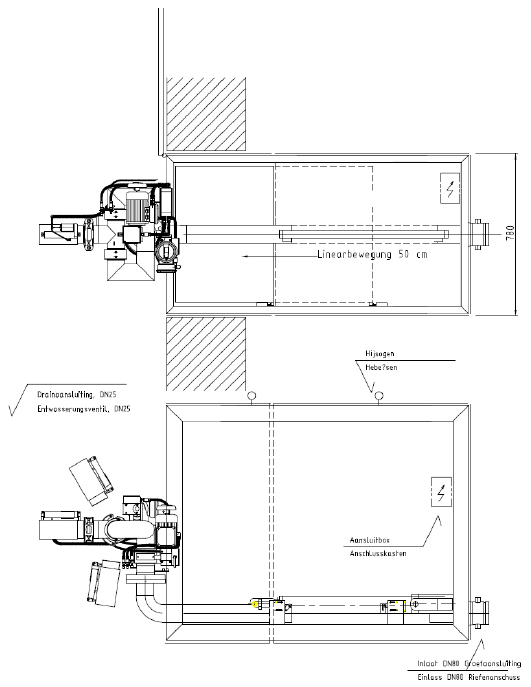

Drawing

Technical specifications

Monitor capacity: Up to 3.000 l/min

Nominal pressure: 16 bar

Maximum operation pressure: 12 bar

Throw length: 55 m (1.600 l/min at 7 bar)

Spray angle of the jet: 120º

Rotation: +/- 90º

Elevation: -80º / +80º

Motor Voltage: 24 Vdc / 230 VAC / 400 VAC

Motor Wattage: 0,36 kW

Roll out distance: 500 mm

Material fire monitor: Stainless steel 1.4404 (316)

Material housing: Carbon steel

Coating: Epoxy coating RAL 3000

PLC oscillation: Optional

Emergency hand operation: Hand wheels