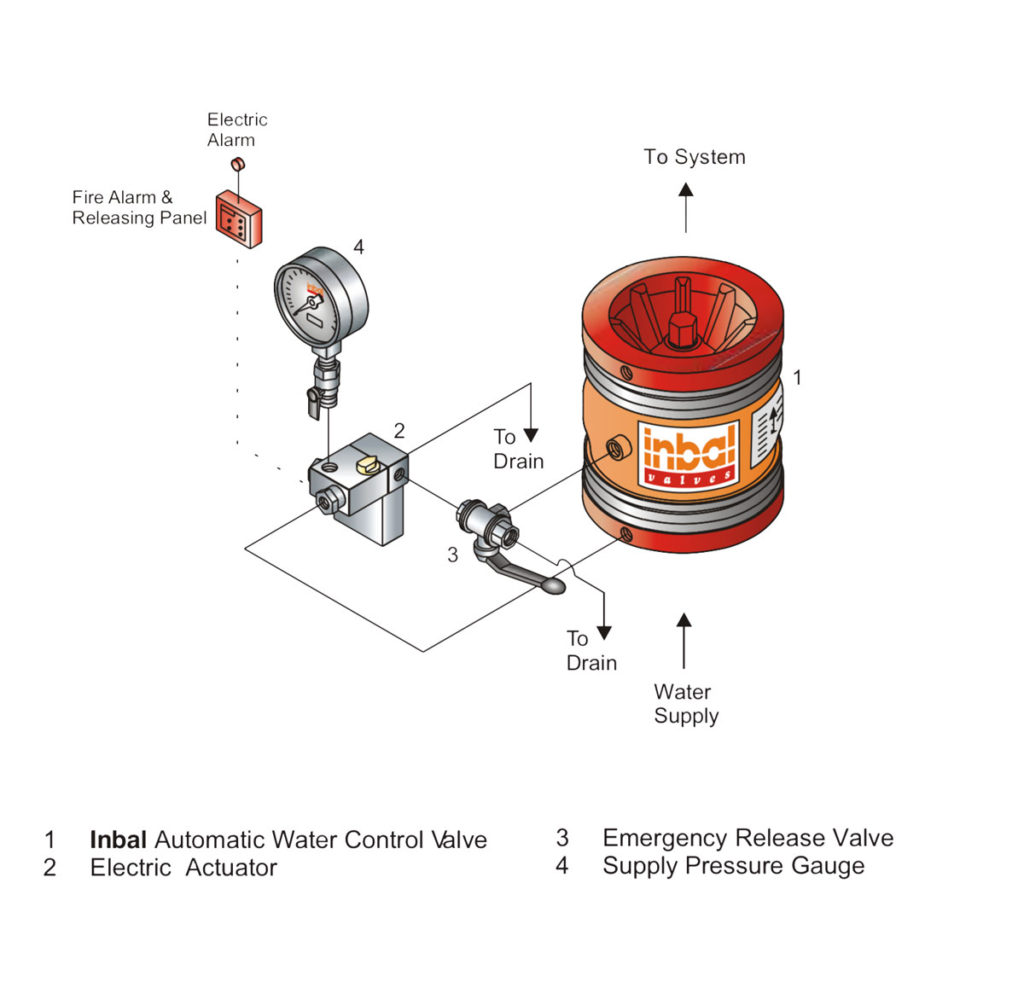

Inbal Control Valve

The Inbal Electrically Actuated Control Valve is specifically designed for use in fire protection systems controlled electrically by automatic or manual release. The series 700D-02C01/2/3/4 consists of Inbal Automatic Water Control Valve series 700D and an Electric Actuator. The Inbal Valve is an automatic streamline sleeve control valve which utilizes only the line pressure as a source of energy to operate.The Inbal Electrically Actuated Control Valve is specifically designed for use in fire protection systems controlled electrically by automatic or manual release. The series 700D-02C01/2/3/4 consists of Inbal Automatic Water Control Valve series 700D and an Electric Actuator. The Inbal Valve is an automatic streamline sleeve control valve which utilizes only the line pressure as a source of energy to operate. The sleeve actuator is an integral part of the Inbal Valve and there are No Moving Mechanical Parts (N.M.M.P.) when the Inbal Valve operates. The Electric Actuator is an integrated multi- functional unit. It consists of a built-in Strainer, Shutoff Valve, Check Valve, and Solenoid Valve. The Electric Actuator is purposely designed for compact, simple, and sturdy control trim.

Model 799D- 02C01

The Electric Actuator utilizes a “dry” concept design and it is easily maintained allowing free, independent access to each device.

The Inbal Electrically Actuated Control Valve is used for local and/or remote operations. The Electric Actuator enables remote electric control with low energy consumption. After operation, the Inbal Control Valve can be remotely reset, saving the need to approach the valve for resetting.

The unique Electrically Actuated Inbal Control Valve can be mounted in any required position with no need to specify the type of installation in advance. The inline shape of the Inbal Valve, together with the integrated Electric Actuator, permits a compact, space saving configuration, protruding only slightly from the pipe lineation. The series 700D-02C01 complies with weather-proof and explosion-proof requirements (an Ex. Pf. coil should be used). An electric flow indicator, an opening speed control, and/or closing speed control are options. The Inbal Control Valve is available in sizes 11⁄2″ (40 mm) to 4″ (100 mm). The valves are available in threaded, wafer, and flanged ends.

The Inbal Control Valve has an excellent operating characteristic. The only moving part is the reinforced sleeve which actuates without delay due to frictionless motion, but at the same time responds to the pressure differential across the valve versus the control pressure, thus moving gradually to prevent any rapid changes in velocity of flow and line pressure. The closure of the Inbal Valve is achieved when the heavy duty sleeve forms a drip-tight seal with the corrosion resistant core.

The standard material Inbal Control Valve is rated to a working pressure of 300 psi (21 bar) but is capable of withstanding severe surges often found in many installations due to pump start- ons or stoppages or other valve operations. The reset of the series 700D- 02C, whether it was operated locally or by remote control, is simply done by restoring the operated release device to set position.

The unique design and variety of materials and coatings make the Inbal Control Valve suitable for use with brackish or sea water similar to those found in chemical and petrochemical facilities or in offshore platforms. It can also be used as a foam concentrate valve in foam / water systems.

The basic Inbal Valve was tested by FM andUL(3″&4″,80&100mm)for300 psi (21 bar) service at 1200 psi (84 bar) hydrostatic pressure and it is part of the FM Approved Inbal Deluge Valve and UL Listed Inbal Pump Pressure Relief Valve. A wide range of various pilot valves and accessories are available when additional duties such as pressure regulating, flow control, or others are required.

Drawing

Specifications

- Maximum working pressure: 230 psi (16 bar)

- Minimum working pressure: 30 psi (2.1 bar)

- Actual pressure rating is limited by the Electric Actuator. Rating to 300 psi (21 bar) is available upon request.

- Temperature Range Water: Max + 150 F(+65 C)

- Installation Position: Vertical or horizontal

Materials

Valve Housing: Carbon Steel (SAE 1021).

Valve Ends: Ductile Iron (ASTM A536 65-45-12).

Sleeve: SMR5 Elastomer reinforced with Poly- ester and Kevlar

Control Trim: Brass Nickel Chrome plated, Stainless Steel.