Betrouwbare schuimmengers

Voor het nauwkeurig bijmengen van schuimconcentraat in de waterstroom van een brandblusinstallatie wordt gebruik gemaakt van verschillende soorten schuimmengers. De keuze van de toe te passen menger hangt af van verschillende aspecten, zoals bijvoorbeeld het type blussysteem, de benodigde capaciteit, de beschikbaarheid energie, de opstelruimte (binnen/buiten/grootte) en de beschikbare druk. Hieronder kunt u per menger een gespecificeerde datasheet downloaden voor meer informatie.Matre Turbine In-line Foam Proportioners are known for their reliability.

The foam proportioner starts to function as soon as water starts to flow through it.

For testing purposes or to run the system with water only it is possible to open the bypass line and send the foam back to the tank. This represents a substantial economic and environmental saving and at the same time increasing safety. It also helps to simplify the firefighting system as auxiliary valves can be omitted.

The simple and robust construction of Matre The robustness in the design of the Turbine In-Line Foam Proportioners ensures low maintenance that is not sensitive to particles in the water.

The foam proportioner starts to function as soon as water starts to flow through it.

For testing purposes or to run the system with water only it is possible to open the bypass line and send the foam back to the tank. This represents a substantial economic and environmental saving and at the same time increasing safety. It also helps to simplify the firefighting system as auxiliary valves can be omitted.

The simple and robust construction of Matre The robustness in the design of the Turbine In-Line Foam Proportioners ensures low maintenance that is not sensitive to particles in the water.

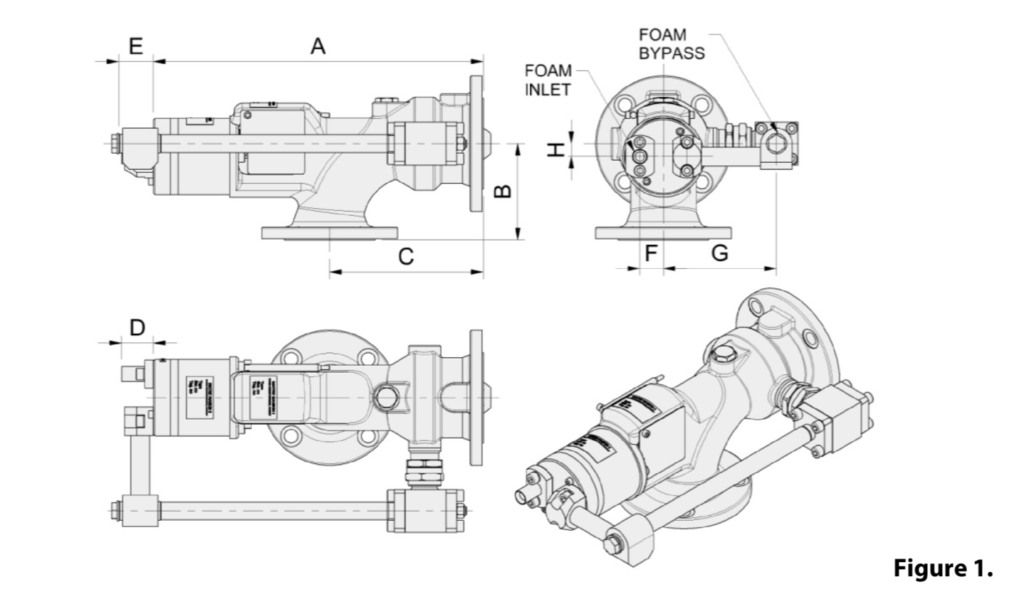

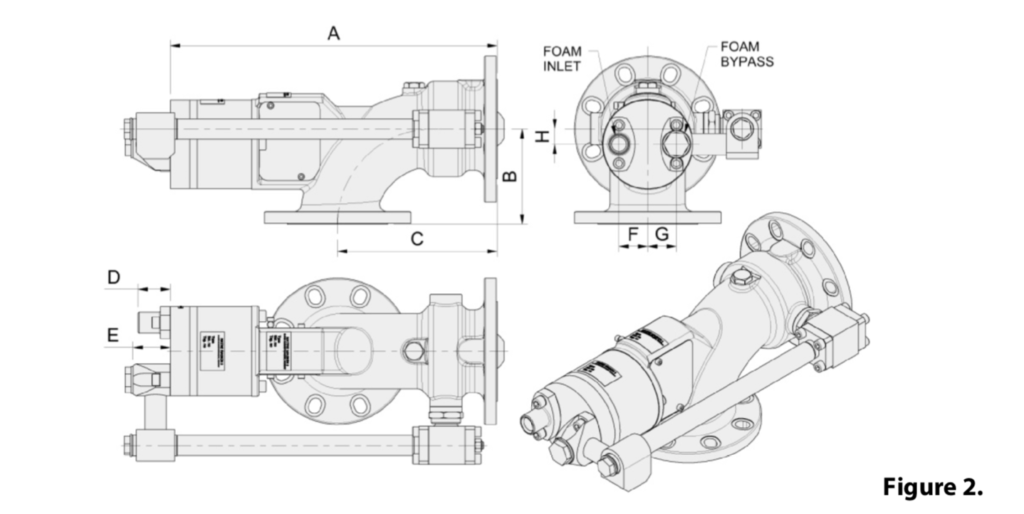

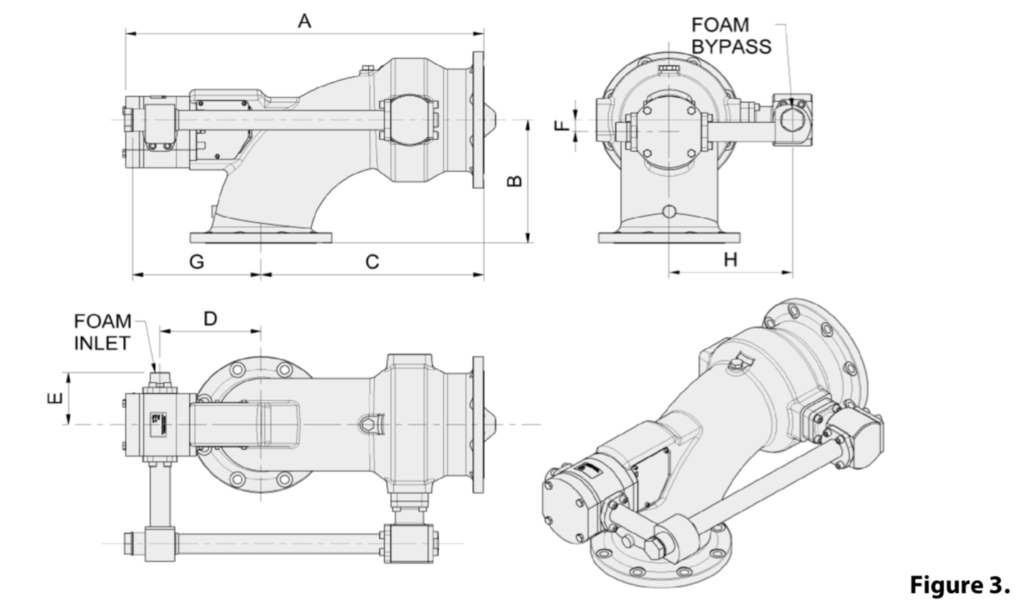

Drawing

Specifications

Material: Bronze BS 1400 AB2 turbine Bronze BS 1400 LB2 pump Stainless Steel AISI 316L manifold

Interface for water supply: ANSI 16.5 150lb RF

Design pressure: 20 bar

Test pressure: 30 bar

Water pressure range: 5-10 bar (5-14 bar)

Pressure loss related to relative flow capacity range: 0,3 – 2,0 bar

Foam concentrate inlet pressure: 0,75 bar abs minimum

Insertion rate: 1% or 3% (Tolerance according to NFPA 11)

Check valve in foam port: Bronze BS 1400 AB2